Who still listens to old-fashioned radios? It’s better to spin a globe and listen to whatever station corresponds to where you spin it.

Have you ever thought about

being able to explore tens of thousands of radio stations around the world

in just a few seconds

simply by spinning a globe?

Then this is your project!

Build a

"RadioGlobe"

Frankly speaking,

even though this technology has existed for many years,

it is still amazing.

Spin the DIY RadioGlobe to find thousands of radio stations

Maybe only flat-Earthers won't like this DIY project

Hey Jude / Instructable

Who still listens to old-fashioned radios these days? They have gradually become a thing of the past, and it’s acceptable that they now exist in the form of streaming media. However, for those who love radio broadcasting, some aspects of it are still powerful.

Inventor Jude Pullen has created the RadioGlobe, which is a perfect gadget for anyone who wants to navigate through the world’s best radio stations in just a few seconds. But it has a quirky twist—you can do this simply by spinning a globe.

To celebrate the 10th anniversary of DesignSpark, Pullen designed this project using an existing tool (one that can receive radio stations). However, as a true inventor, he took the receiver to the next level by adding fully DIY and open-source elements.

# He aimed to achieve "open exploration and a love for discovery," and he built this project using basic tools such as a drill, a soldering iron, a file, and a drill bit.

He provided instructions on how to build it on Instructables; however, before rolling up your sleeves, you should know that this project requires intermediate/expert-level expertise.

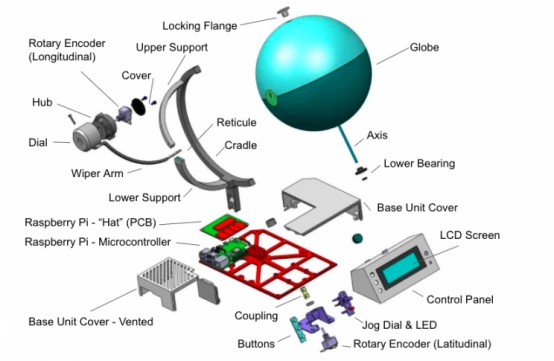

For those interested in building one themselves, hands-on use of a Raspberry Pi 4B, bolts, an LCD screen, buttons, a roller wheel, a prototype board for Raspberry Pi, RGB LEDs, jumper wires, pin headers, steel rods, and a 3D printer is required.

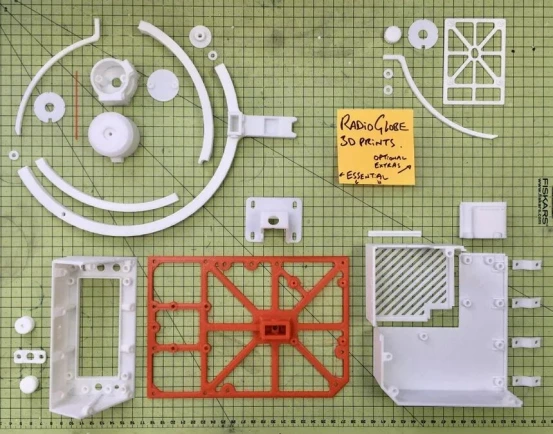

3D printed parts:

As shown in the figure, I recommend using a 0.6mm or smaller nozzle to print parts with fine details, such as dials and display panels.

After that, you can either maintain a similar quality, or print the case and "stand" components at a coarser printing resolution (e.g., with a 1.0mm nozzle),

as shown in the figure.